Consumer products need to be packed in attractive packaging,

the cost of which can eat into your profit margins. Manufacturers of high value

products can afford glitzy packaging but for mass produced and mass sold items

with slim profit margins, packaging must be optimised so that it serves as a

promotional material but at a lower cost. In such a scenario, Banding is the

answer!

What Is Banding?

Banding consists of wrapping a printed band around a pack.

The band may be as wide as 2

inches or as narrow as a half inch, and it can be made

of polymer material as thin as 35 microns. Rolls of pre-printed bands may be

fitted to the dispenser of a banding machine, and as the products move on a

conveyor, the machine dispenses the band which is wrapped around the package.

It not only enhances brand appeal but also serves as a tamper-proof seal

thereby enhancing confidence in the quality of the product.

The Need For Banding Equipment

One can, of course, apply the band manually or by using a

manual tool. However, most consumer products are sold in bulk and at low

margins and banding must keep step with output of the packaging equipment.

Installing banding equipment to take care of banding is a logical step.

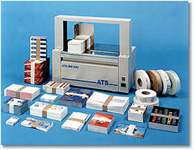

However, there are differences in the types of machines

available to suit the package and the way the band needs to be applied. One

machine for banding purposes also handles bundling. It allows for rotation of

product to be banded. In a high volume production environment a conveyorised

banding system is preferred for fast and accurate as well as precision

application of the bands on a variety of packaging that can include boxes,

trays and punnels. Typical areas of application are consumer and food products.

The band also serves as a tamper-proof seal. Then there are instances when

multiple packs may need to be banded together to form a bundle for which

another type of equipment for banding can be used. Machines are best selected

based on the end product, its size and structure as well as its rigidity.

Buying the machine from a reliable supplier with experience

and knowledge in this area is a good idea. If the same supplier also offers

consumables, then it is an additional treat that you should go for.